| Part Number | LNK408EG |

|---|---|

| Manufacturer | Power Integrations |

| Description | IC LED DRIVER OFFL DIM ESIP-7C |

| Datasheet | |

| Package | 7-SIP, 6 Leads, Exposed Pad, Formed Leads |

| ECAD |

|

| In Stock | 82,668 piece(s) |

| Unit Price | Request a Quote |

| Lead Time | Can Ship Immediately |

| Estimated Delivery Time | Apr 21 - Apr 26 (Choose Expedited Shipping) |

| Request for Quotation |

|

| Payment Methods | |

| Delivery Services |

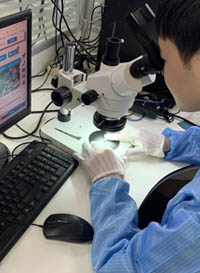

Part Number # LNK408EG (PMIC - LED Drivers) is manufactured by Power Integrations and distributed by Heisener. Being one of the leading electronics distributors, we carry many kinds of electronic components from some of the world’s top class manufacturers. Their quality is guaranteed by its stringent quality control to meet all required standards.

For LNK408EG specifications/configurations, quotation, lead time, payment terms of further enquiries please have no hesitation to contact us. To process your RFQ, please add LNK408EG with quantity into BOM. Heisener.com does NOT require any registration to request a quote of LNK408EG.

Kel*****Anne

April 3, 2023

Nyl*****Pitts

March 2, 2023

Aali*****Mangat

February 26, 2023

We guarantee 100% customer satisfaction.

Our experienced sales team and tech support team back our services to satisfy all our customers.

We provide 90 days warranty.

If the items you received were not in perfect quality, we would be responsible for your refund or replacement, but the items must be returned in their original condition.

| Part Number | Manufacturer | Description | Stock |

LNK408EG D# LNK408EG |

Power Integrations |

LED DRVR 6-Pin ESIP-7C - Rail/Tube (Alt: LNK408EG) RoHS: Compliant

|

0 |

| Part Number | Manufacturer | Description | Stock |

LNK408EG D# LNK408EG |

Power Integrations |

LED DRVR 6-Pin ESIP-7C (Alt: LNK408EG) RoHS: Compliant

|

0 |

| Part Number | Manufacturer | Description | Stock |

LNK408EG |

Power Integrations |

Power Integrations LNK408EG |

34 |

| Part Number | Manufacturer | Description | Stock |

LNK408EG |

POWER |

In stock shipping within 2days |

6260 |

| Part Number | Manufacturer | Description | Stock |

LNK408EG D# 2266247 |

Power Integrations |

DRIVER, LED, 85-308VAC, 35W, 7SIP RoHS: Compliant

Min Qty: 1

Container: Each

|

0 |

| Part Number | Manufacturer | Description | Stock |

LNK408EG |

Power Integrations |

RoHS: Compliant

pbFree: Yes

|

0 |

| Part Number | Manufacturer | Description | Stock |

LNK408EG |

POWER |

OEM/CM Immediate delivery |

6000 |

| Part Number | Manufacturer | Description | Stock |

LNK408EG D# 869-LNK408EG |

Power Integrations |

LED Lighting Drivers LED DrvrTRIAC Dim 35 W (85-265 VAC) RoHS: Compliant

|

63 |

| Part Number | Manufacturer | Description | Stock |

LNK408EG D# NS-LNK408EG |

Power Integrations |

OEM/CM ONLY |

8589 |

| Part Number | Manufacturer | Description | Stock |

LNK408EG |

POWER |

IN stock Immediate delivery |

6015 |

| Part Number | Manufacturer | Description | Stock |

LNK408EG |

POWER |

shipping today |

5999 |

Heisener's commitment to quality has shaped our processes for sourcing, testing, shipping, and every step in between. This foundation underlies each component we sell.

Do you have any question about LNK408EG?

+86-755-83210559 ext. 809

Scan to view this page