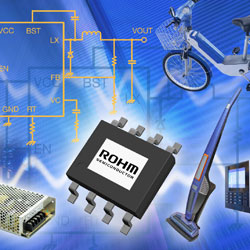

Rohm has introduced a new 12V to 76V input, 3A variable output voltage, DC-DC step-down converter with integrated 76V MOSFET, suitable for motors, factory automation equipment, communication infrastructure And industrial applications such as high power (high voltage x high current) application machinery.

In recent years, with the increasing importance of energy conservation in all areas, the use of high-power semiconductor devices and power ICs has promoted even greater power to achieve energy savings in the field of industrial equipment. Therefore, it is necessary to provide a breakdown voltage higher than the input voltage to prevent damage due to transient surges and transient voltages (such as those caused by lightning).

In response, Rohm uses its advanced cutting-edge power technology and vertically integrated production systems to develop products suitable for the industrial equipment market. These products require long-term, stable supply and high reliability to achieve continuous operation.

BD9G341AEFJ utilizes a proprietary 0.6um high-voltage BiCDMOS process to achieve the industry's leading maximum breakdown voltage of 80V (the highest voltage in ROHM's non-isolated DC / DC converter product lineup) and a continuous operating input range of 12 to 76V. Proven advanced analog design technology enables the highest conversion efficiency in its class. In addition, compared with conventional products, multiple protection circuits can minimize heat generation even during short-circuit (contact) of the output pins, preventing possible damage and improving reliability. The company said that the compact 8-pin package requires fewer parts and reduces mounting area, which helps simplify PCB placement and miniaturization of the final product.