|

ABM11W-37.4000MHZ-7-D1X-T3 |

Abracon LLC, CRYSTAL 37.40MHZ 7PF SMT, 4-SMD, No Lead, MIL-DTL-38999 Series III, Tri-Start? HD |

View

|

|

VJ0603D201GXXAR |

Vishay Vitramon, CAP CER 200PF 25V C0G/NP0 0603, 0603 (1608 Metric), MIL-DTL-38999 Series III, Tri-Start? HD |

View

|

|

CL10C0R5BB8NNNC |

Samsung, CAP CER 0.5PF 50V C0G/NP0 0603, 0603 (1608 Metric), MIL-DTL-38999 Series III, Tri-Start? HD |

View

|

|

MVKBP50VCR33MD60TP |

United Chemi-Con, CAP ALUM 0.33UF 20% 50V SMD, Radial, Can - SMD, MIL-DTL-38999 Series III, Tri-Start? HD |

View

|

|

MXLPLAD18KP8.5CAE3 |

Microsemi Corporation, TVS DIODE 137VC 132A PLAD, Nonstandard SMD, MIL-DTL-38999 Series III, Tri-Start? HD |

View

|

|

RN60C6193FRSL |

Vishay Dale, RES 619K OHM 1/4W 1% AXIAL, Axial, MIL-DTL-38999 Series III, Tri-Start? HD |

View

|

|

ISC1210EB22NK |

Vishay Dale, FIXED IND 22NH 640MA 150 MOHM, 1210 (3225 Metric), MIL-DTL-38999 Series III, Tri-Start? HD |

View

|

|

1727040048 |

Molex, LLC, CONN D-SUB RCPT 25POS PNL MNT, -, MIL-DTL-38999 Series III, Tri-Start? HD |

View

|

|

MS3452LS24-28P |

Amphenol Aerospace Operations, CONN RCPT 24POS BOX MNT W/PINS, -, MIL-DTL-38999 Series III, Tri-Start? HD |

View

|

|

GTC01A28-21P |

Amphenol Industrial Operations, GT 37C 37#16 PIN RECP, -, MIL-DTL-38999 Series III, Tri-Start? HD |

View

|

|

8LT315B15PB-LC |

Souriau, CONN RCPT HSNG MALE 15POS PNL MT, -, MIL-DTL-38999 Series III, Tri-Start? HD |

View

|

|

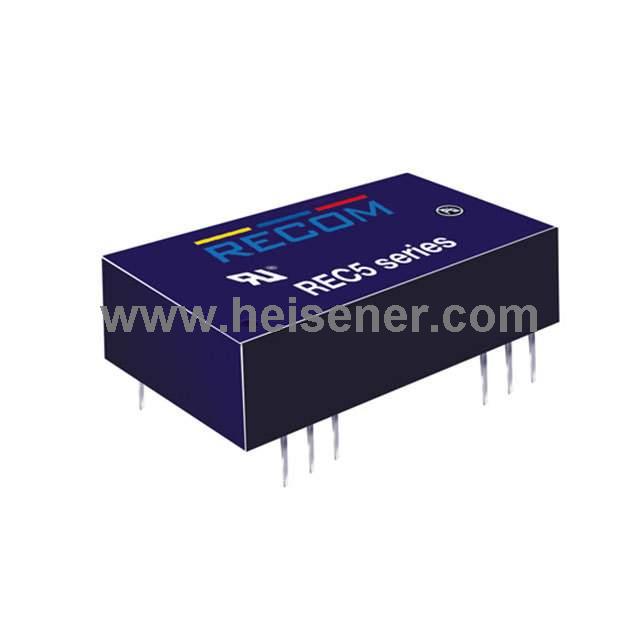

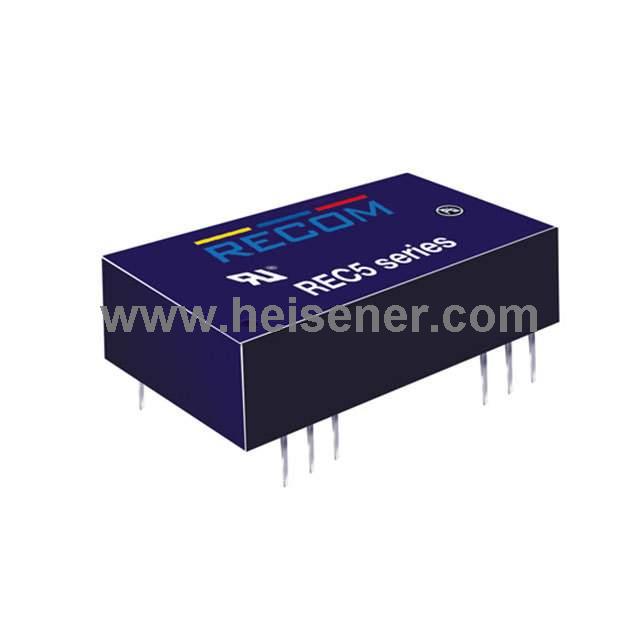

REC5-2415SRW/H2/A/M |

Recom Power, CONV DC/DC 5W 18-36VIN 15VOUT, 24-DIP Module, 8 Leads, MIL-DTL-38999 Series III, Tri-Start? HD |

View

|